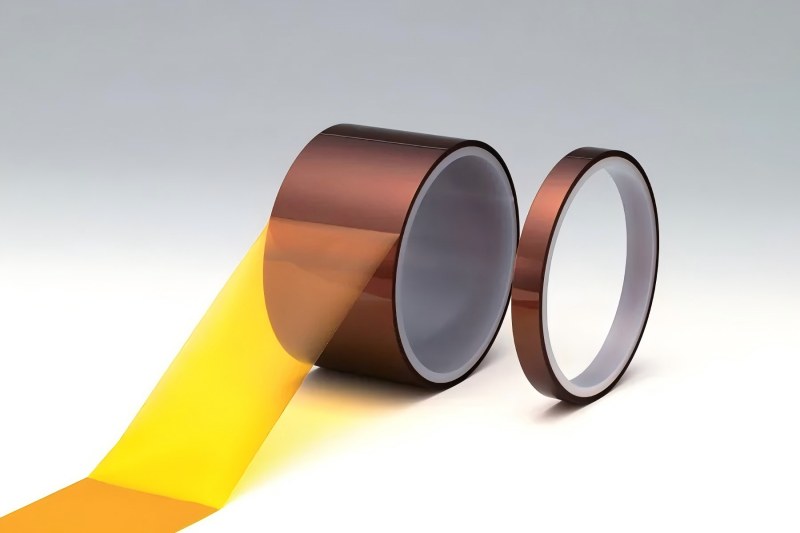

Walk into any modern electronics factory, an automotive assembly line, or even a hobbyist's 3D printing workshop, and you'll find a silent, often unseen workhorse: polyimide tape. You might know it by its common nickname—"Kapton tape," a name derived from a leading manufacturer. But what exactly is this amber-colored tape, and why is it so indispensable across so many industries?

In simple terms, polyimide tape is a specialty adhesive tape designed to perform where others fail. Its core is a polyimide film, a material renowned for its incredible strength and resistance to extreme temperatures. This film is then coated with a high-performance adhesive, like silicone or acrylic, turning it into a versatile tool for insulation, protection, and masking.

This article will dive deep into the world of polyimide tape. We'll explore its properties, its countless applications, and why choosing the right polyimide tape manufacturer is crucial for your project's success.

To understand its value, you need to look at its construction. The magic starts with the polyimide film base. This film isn't just tough; it's a champion of stability. It doesn't melt, burn, or become brittle easily. When this film is combined with a robust adhesive, you get a product with a unique set of capabilities:

•Incredible Heat Resistance: This is its standout feature. Standard tapes might fail at 100°C or 150°C. In contrast, polyimide tape consistently operates in a polyimide temperature range from -269°C to over 400°C for short periods. This makes it perfect for processes involving soldering, baking, or high-temperature curing.

•Superior Electrical Insulation: As an excellent polyimide electrical insulation tape, it provides a critical barrier against short circuits. Its high dielectric strength (often ≥6 kV/mm) ensures it can protect sensitive components and windings in motors and transformers, even under high voltage stress.

•Chemical and Solvent Resistance: It stands up to exposure to most solvents, oils, and fuels without degrading, swelling, or losing its adhesive properties. This is vital in automotive and aerospace applications.

•Exceptional Strength: Despite being thin, the polyimide film has a very high tensile strength. It resists tearing and can withstand significant physical stress during application and use.

•Precision and Cleanliness: High-quality polyimide tape, like that produced by QKD with over 15 years of expertise, is coated to a precision of ±2.5µm. This means it's free from defects like scratches or "gum streaks," ensuring a flawless, reliable surface. It is also designed for clean removal, leaving little to no residue.

The unique properties of polyimide tape make it a problem-solver in countless scenarios. Let's break down its uses by sector.

(1)Electronics and PCB Manufacturing: The Guardian of Circuit Boards

This is where polyimide tape is most at home. Its primary role is protection during the most aggressive stages of production.

•SMT and Wave Soldering: During soldering, certain parts of a circuit board—like gold fingers or sensitive connectors—must be shielded from molten solder. Polyimide tape acts as a protective mask, enduring the intense heat of the soldering process and peeling away cleanly afterward without contaminating the surface.

•Electrical Insulation: It is the go-to tape for insulating transformer and motor coils. Its ability to maintain integrity at high temperatures makes it ideal for "H-class" motors, which run hotter and demand more from their insulating materials.

•Component Protection: It's used to secure and protect fragile components like capacitors and resistors from heat, dust, and moisture, ensuring the long-term reliability of the device.

(2)The Rise of Polyimide Tape for 3D Printing

The 3D printing community has wholeheartedly adopted this tape, and for good reason.

•Print Bed Adhesion: Many printers use polyimide tape as a build surface. Its smooth, heat-resistant surface provides an excellent foundation for the first layer of a print, helping it stick securely during printing.

•Heated Bed Protection: For printers with heated beds, applying this tape directly to the bed protects it from scratches, plastic residue, and other damage. It can handle the bed's polyimide temperature without degrading.

•Part Protection and Insulation: Advanced users also use it to insulate printer components like hot ends and heater blocks, stabilizing temperatures and improving print quality.

(3)Aerospace and Automotive: Demanding Environments, Reliable Performance

In these fields, failure is not an option. Components must withstand vibration, extreme temperatures, and harsh chemicals.

•Aerospace: Satellites and spacecraft experience wild temperature swings and radiation. Polyimide tape is used for wire and cable harness insulation because it remains stable under these brutal conditions, contributing to the vehicle's long-term operational life.

•Automotive: Under the hood, temperatures can soar. Polyimide electrical insulation tape is used to wrap and protect wiring harnesses near engines and exhaust systems. Its resistance to oil, fuel, and abrasion makes it a durable, long-lasting solution that reduces circuit failure rates.

(4)General Industrial Manufacturing: The Master of Masking

Beyond electronics, its heat resistance makes it perfect for masking.

•High-Temperature Painting and Coating: When metal parts need selective painting or powder coating, double sided polyimide masking tapes and single-sided versions are used to cover areas that must remain paint-free. They withstand the high heat of curing ovens and then remove cleanly, leaving a sharp, clean edge.

•Surface Protection: Its strength and chemical resistance make it ideal for protecting sensitive surfaces during machining, shipping, or assembly.

Not all polyimide tapes are the same. The choice of adhesive can drastically change its performance.

Silicone Adhesive: This is the classic choice for the most extreme high-temperature applications. It offers excellent polyimide temperature resistance, often up to 260°C continuously. It provides a strong, durable bond.

Polyimide Tape with Acrylic Adhesive: Acrylic adhesives generally offer higher initial tack (stickiness) and better resistance to solvents. They are often used in applications requiring a very strong bond at slightly lower, but still high, temperatures. They are also known for clean removability, which is crucial in masking applications.

Furthermore, tapes come in different forms. While single-sided is standard, double sided polyimide masking tapes are essential for holding parts in place during processes like spray painting or chemical etching, where a secure, temporary bond is needed.

With such critical applications, the quality and consistency of the tape are non-negotiable. This is where the experience of the polyimide tape manufacturer becomes paramount. A company like QKD doesn't just sell tape; it provides engineered solutions.

With over 15 years of specialization, QKD has honed its manufacturing process to deliver products that meet the strictest standards. Our expertise ensures:

•Precision Coating: Our coating process achieves an accuracy of ±2.5µm, guaranteeing a uniform adhesive layer free from defects. This translates to consistent performance every time.

•Superior Materials: We use only the highest-grade polyimide film and pair it with the right adhesive—whether silicone or a high-performance polyimide tape with acrylic adhesive—for the specific application.

•Customization: We understand that one size doesn't fit all. We offer low-static and flame-retardant variants and can work with clients to develop tapes for unique challenges.

•Rigorous Testing: Every batch is tested to ensure it meets specifications for thickness, adhesion, dielectric strength, and temperature resistance, adhering to standards like ASTM D-3652.

When you source from QKD, you're not just buying a roll of tape; you're leveraging a decade and a half of expertise to ensure your product is reliable, safe, and effective.

From the smartphone in your pocket to the car you drive and the satellites orbiting our planet, polyimide tape plays a vital, though often hidden, role. Its unparalleled combination of heat resistance, electrical insulation, and physical toughness makes it an enabling technology for innovation.

Whether you are a PCB designer, a 3D printing enthusiast, or an engineer in the aerospace sector, understanding the capabilities of this remarkable material is key. And when you need a tape you can trust, partnering with an experienced polyimide tape manufacturer like QKD ensures that this invisible hero will perform flawlessly, protecting your work and powering your progress.

Ready to find the right polyimide tape for your project? Explore the QKD range of high-performance solutions and leverage our 15+ years of expertise today.

RELEVANT POSTS >